ROSLER CONSUMABLES:

UNIFORMITY FOR MASS FINISHING

The most comprehensive range of consumables in the world

Rosler produces plastic finishing media, chemical treatment agents (compounds) and has over 60 years of experience in the production of ceramic media. Consumables are our tools, and we know how to the get the best results with them. Our portfolio contains over 15,000 products and is thus the most comprehensive program in the world.

All Rosler Group consumables are developed in our own testing centers and labs in Germany. They meet the highest ecological standards and can be individually adapted to the requirements and wishes of our customers. We monitor the quality of our consumable production through quality controls pursuant to DIN EN ISO 9011 and 50001.

Why Choose Rösler As Your Partner In Aviation?

THE ULTIMATE IN COMPOUND DEVELOPMENT

In the past, mass finishing chemicals were mainly alkaline and chelating. Today, our compounds are based on organic substances, which are almost completely biodegradable. A computer-controlled mixing process, and constant quality controls in our own laboratories ensure that our high quality standards are met.

We are constantly developing special compounds for solutions to specific problems.

- Liquid Compounds

- Recycling Compounds

- Powder Compounds

- Grinding compounds

- Polishing compounds

- Dry-polishing compounds

- Cleaning (degreasing) Compounds

CERAMIC MEDIA – A MILESTONE IN MEDIA DEVELOPMENT

Required finishing results, machine size and the weight of the treated parts, are important aspects in choosing the right media composition and size to achieve the optimum process. Different types of media with varying amounts of abrasive are needed for the various processes.

Rösler manufactures various sizes and compositions of ceramic media in our production facilities. This ensures that the right media is available for each application. Special customer specific solutions can also be produced. Our test labs and our media production facilities work together to develop media that meets special requirements. All consumables – ceramic and plastic media, compounds, and auxiliary media are manufactured to the highest quality standards. Our eight-step quality checks guarantee the consistent quality of our products. All production areas are certified to DIN ISO 9001 standards.

CONSISTENTS RESULTS WITH PLASTIC – BONDED GRINDING MEDIA

Plastic medias are generally used for a more gentle treatment of parts. The specific gravity, and therefore the bulk weight of plastic media, is almost half that of ceramic media. Our computer-controlled manufacturing process and the special curing treatment after de-molding, guarantees the consistent high quality of our media. This is the key to a repeatable process, which guarantees consistent finishes and therefore, the quality of our customers” products.

POLISHING AND DRYING MEDIA – AUXILIARY MEDIAS COMPLETE THE CONSUMABLES PRODUCT LINE

Polishing and drying media are important process aids, for achieving consistent mass finishing results.Stainless steel balls, ballcones or satellites, and stainless steel pins are used for burnishing and deburring ferrous and non-ferrous parts. Corn cob drying media is used in rotary dryers and drum dryers in which parts can be dried without water spots, cleaned, or polished. Glass beads are also used for polishing. Anti-adhesion balls are used to prevent flat, thin parts from sticking together.

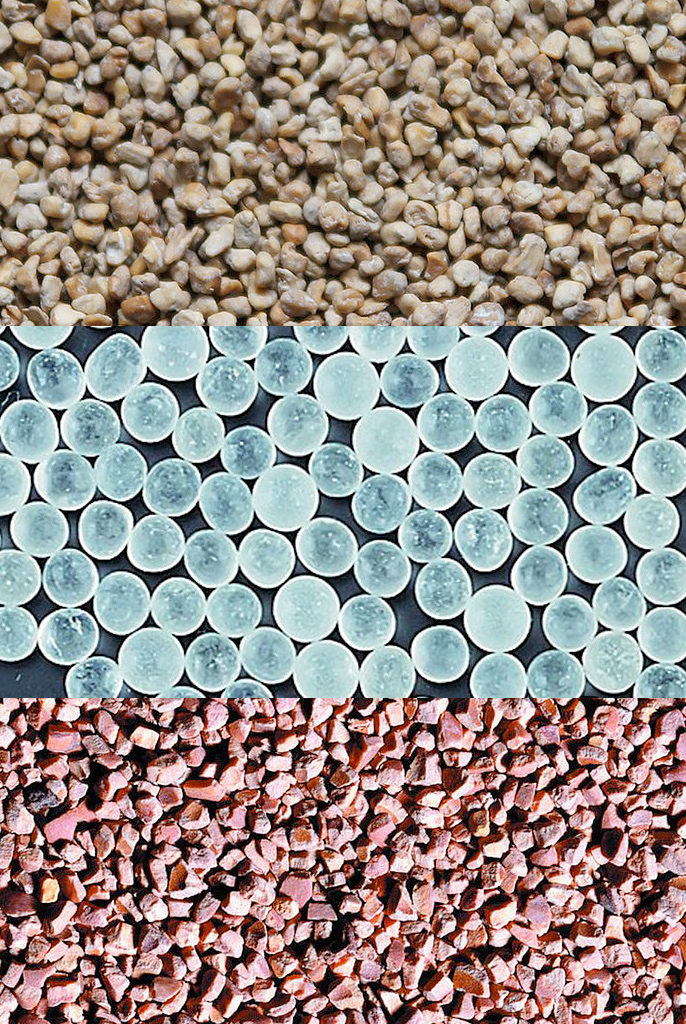

SHOT-BLASTING MEDIA FOR ALL APPLICATIONS

The large variety of shot blasting applications requires an even larger variety of shot blast media. The media not only affects the required finish, but also has to meet other requirements, such as long life, low wear, and short treatment times. Based on our experience and the available assortment of shot blast media, we can recommend the optimum media for your application. Whether it is metallic or non-metallic, sharp or round grained, we can supply you with materials of almost any hardness.

The Rösler quality control lab constantly monitors the quality of shot blast media to supply you with consistent products to achieve consistent top quality results. Research and development in our testing facilities and in the field, ensures that our shot blast media is continuously improved. Today “shot” is no longer just an auxiliary media, but a significant aspect in cost savings and quality improvements in your shot blasting application.

- Stainless steel

- Chilled cast iron

- Cast steel

- Glass beads

- Ceramic balls

- Aluminium shot

- Mixed corundum

- Standard corundum

- Pure corundum

- Duroplast shot-blasting media

- Polyamide shot-blasting media

- Cut wire shot

- Polycarbonate

- Antistatic agents